Μια αυτόματη μηχανή πωματισμού είναι ένα κρίσιμο κομμάτι εξοπλισμού σε σύγχρονες γραμμές παραγωγής και η σταθερή λειτουργία της σχετίζεται άμεσα με την αποδοτικότητα της συσκευασίας και την ποιότητα του προϊόντος. Αυτός ο οδηγός παρέχει μια λεπτομερή λίστα αντιμετώπισης προβλημάτων για να σας βοηθήσει να εντοπίσετε και να λύσετε γρήγορα κοινά προβλήματα με την αυτόματη μηχανή πωματισμού σας, ελαχιστοποιώντας τον χρόνο διακοπής λειτουργίας.

Μια αυτόματη μηχανή πωματισμού χρησιμοποιεί μια ακριβή μηχανική δομή, ένα πνευματικό σύστημα ή έλεγχο σερβο για να παραλαμβάνει, να τοποθετεί και να σφίγγει αυτόματα τα καπάκια των φιαλών. Αυτές οι μηχανές διαδραματίζουν ζωτικό ρόλο σε διάφορες βιομηχανίες όπως τα τρόφιμα και τα ποτά, τα φαρμακευτικά προϊόντα, τα καλλυντικά και τα χημικά, όπου η ποιότητα του πωματισμού επηρεάζει άμεσα την ακεραιότητα της σφράγισης και την ασφάλεια ενός προϊόντος.

Λίστα Ετοιμασίας και Ασφάλειας

Πρώτα η ασφάλεια: Πριν ξεκινήσει οποιαδήποτε εργασία, βεβαιωθείτε ότι η μηχανή είναι εντελώς σταματημένη. Απενεργοποιήστε και κλειδώστε τις πηγές ρεύματος και αέρα και τοποθετήστε μια ετικέτα προειδοποίησης ασφαλείας στον εξοπλισμό.

Συγκεντρώστε τα εργαλεία σας: Έχετε έτοιμα όλα τα απαραίτητα εργαλεία συντήρησης, συμπεριλαμβανομένου ενός κλειδιού ροπής, ενός σετ κλειδιών Allen, ενός σετ κατσαβιδιών και μετρητικών στροφών.

Βασικά έγγραφα: Κρατήστε το εγχειρίδιο λειτουργίας του εξοπλισμού, τα ηλεκτρικά διαγράμματα και τη λίστα ανταλλακτικών κοντά σας.

Συνηθισμένες βλάβες και βήμα προς βήμα λύσεις για αυτόματες μηχανές πωματισμού

1. Λανθασμένη ροπή πωματισμού

Συμπτώματα:

- Το καπάκι είναι πολύ σφιχτό: Μπορεί να οδηγήσει σε παραμόρφωση της φιάλης ή να δυσκολέψει τον τελικό χρήστη να το ανοίξει.

- Το καπάκι είναι πολύ χαλαρό: Προκαλεί διαρροή του προϊόντος, θέτοντας σε κίνδυνο τη σφράγιση και την ακεραιότητα του προϊόντος.

Βήματα αντιμετώπισης προβλημάτων:

- Βαθμονόμηση ρυθμίσεων ροπής: Χρησιμοποιήστε ένα επαγγελματικό μετρητή δοκιμής ροπής για να βαθμονομήσετε τη μηχανή. Ρυθμίστε τον συμπλέκτη τριβής ή τις παραμέτρους του σερβοκινητήρα σύμφωνα με τις συγκεκριμένες απαιτήσεις ροπής του προϊόντος σας.

- Ελέγξτε το πνευματικό σύστημα: Επιβεβαιώστε ότι η πίεση του αέρα είναι σταθερή εντός του συνιστώμενου εύρους των 0,6-0,8 MPa. Επίσης, ελέγξτε ότι η βαλβίδα μείωσης πίεσης λειτουργεί σωστά για να εξασφαλίσετε σταθερή παροχή αέρα.

- Επιθεωρήστε για φθορά: Εξετάστε προσεκτικά τα μαξιλαράκια τριβής, τους λαβές και τα δακτυλίδια O στο κεφάλι πωματισμού. Η φθορά σε αυτά τα εξαρτήματα μπορεί να οδηγήσει σε ασταθή ροπή. Αντικαταστήστε τα όπως απαιτείται.

- Ρυθμίστε τις ρυθμίσεις ύψους: Επαναβαθμονομήστε το κάθετο ύψος του κεφαλιού πωματισμού. Βεβαιωθείτε ότι έρχεται σε ακριβή επαφή με το λαιμό της φιάλης για να αποφύγετε προβλήματα που προκαλούνται από ακατάλληλη επαφή.

2. Αποτυχία αρπαγής και ρίψης καπακιού

Συμπτώματα:

- Το κεφάλι πωματισμού δεν καταφέρνει να πιάσει ένα καπάκι από την τσουλήθρα.

- Το καπάκι πέφτει κατά τη διαδικασία πωματισμού πριν ασφαλιστεί.

Λύσεις:

1. Ελέγξτε την ποιότητα των καπακιών: Μετρήστε τα καπάκια για να βεβαιωθείτε ότι οι διαστάσεις τους πληρούν τις προδιαγραφές. Τα παραμορφωμένα καπάκια ή αυτά με γρέζια είναι μια συνηθισμένη αιτία αποτυχιών αρπαγής.

2. Επιθεωρήστε τη συσκευή αρπαγής:

- Μηχανικός τύπος: Ελέγξτε εάν η τάση του ελατηρίου των λαβών έχει εξασθενήσει ή εάν οι ίδιοι οι λαβές έχουν φθαρεί.

- Τύπος κενού: Δοκιμάστε τη στεγανοποίηση των γραμμών κενού και καθαρίστε ή αντικαταστήστε τις βεντούζες για να εξασφαλίσετε επαρκή δύναμη κενού.

3. Καθαρίστε την τσουλήθρα καπακιών: Αφαιρέστε τυχόν υπολείμματα ή σπασμένα καπάκια από την τσουλήθρα καπακιών. Ρυθμίστε το πλάτος της τσουλήθρας για να εξασφαλίσετε ομαλή ροή των καπακιών.

3. Λοξός ή στραβός πωματισμός

Συμπτώματα: Το καπάκι δεν είναι παράλληλο με το άνοιγμα της φιάλης και φαίνεται στραβό.

Μέθοδοι αντιμετώπισης προβλημάτων:

- Επιθεωρήστε την ποιότητα της φιάλης: Επιβεβαιώστε ότι οι φιάλες δεν είναι παραμορφωμένες και ότι όλα τα ανοίγματα των φιαλών είναι ομοιόμορφα σε μέγεθος.

- Ρυθμίστε τη συσκευή κεντραρίσματος: Βαθμονομήστε τον μηχανισμό συγκράτησης της φιάλης (π.χ., πλευρικές ζώνες ή σφιγκτήρες) για να διασφαλίσετε ότι η φιάλη είναι ακριβώς στο κέντρο καθώς εισέρχεται στον σταθμό πωματισμού.

- Ελέγξτε τη συγκεντρικότητα της μηχανής: Βεβαιωθείτε ότι το κεφάλι πωματισμού, η υποστήριξη της φιάλης και ο ιμάντας μεταφοράς είναι όλα τέλεια ευθυγραμμισμένα. Η συγκεντρικότητα είναι ζωτικής σημασίας για τον ίσιο πωματισμό.

- Επαληθεύστε το επίπεδο της μηχανής: Χρησιμοποιήστε ένα αλφάδι για να ελέγξετε εάν η μηχανή είναι εγκατεστημένη σε μια επίπεδη επιφάνεια. Μια ανώμαλη βάση μπορεί να προκαλέσει τρέμουλο και λοξό πωματισμό.

4. Εμπλοκή και μπλοκάρισμα καπακιού

Συμπτώματα: Τα καπάκια κολλάνε στο μπολ διαλογής καπακιών ή στην τσουλήθρα παράδοσης.

Γρήγορες διορθώσεις:

- Σταματήστε τη μηχανή αμέσως: Απενεργοποιήστε τον εξοπλισμό και αφαιρέστε τυχόν ξένα αντικείμενα ή σπασμένα καπάκια από το μπολ διαλογής και την τσουλήθρα.

- Ρυθμίστε το κενό της τσουλήθρας: Ταιριάξτε το κενό της τσουλήθρας με τις διαστάσεις του καπακιού για να εξασφαλίσετε ομαλή διέλευση.

- Επιθεωρήστε τον δίσκο διαλογής: Ελέγξτε για φθορά στις ράβδους οδηγού του δίσκου διαλογής και ρυθμίστε την ταχύτητα περιστροφής του δίσκου όπως απαιτείται.

5. Ασυνήθιστος θόρυβος και δόνηση

Συμπτώματα: Η μηχανή παράγει ασυνήθιστους θορύβους ή υπερβολική δόνηση κατά τη λειτουργία.

Βασικά σημεία επιθεώρησης:

- Ελέγξτε τα συνδετήρες: Πραγματοποιήστε έναν ολοκληρωμένο έλεγχο όλων των μπουλονιών και των βιδών στη μηχανή. Η παρατεταμένη δόνηση μπορεί να τα χαλαρώσει.

- Λίπανση και συντήρηση: Ανατρέξτε στο εγχειρίδιο της μηχανής και προσθέστε τη σωστή ποσότητα λιπαντικού στα ρουλεμάν, τις ράγες οδηγού και άλλα κινούμενα μέρη για να μειώσετε την τριβή.

- Επιθεωρήστε το σύστημα κίνησης: Ελέγξτε την τάση των ιμάντων και επιθεωρήστε τα γρανάζια για τυχόν ζημιές ή ελλείποντα δόντια.

6. Βλάβες του ηλεκτρικού συστήματος ελέγχου

Συμπτώματα: Η μηχανή δεν ανταποκρίνεται ή οι κινήσεις της είναι ακανόνιστες.

Διαγνωστικές μέθοδοι:

- Ελέγξτε τους αισθητήρες: Καθαρίστε όλους τους φωτοηλεκτρικούς αισθητήρες και τους διακόπτες εγγύτητας. Η σκόνη ή η βρωμιά μπορεί να επηρεάσουν τα σήματά τους. Ρυθμίστε την απόσταση ανίχνευσής τους εάν είναι απαραίτητο.

- Επιθεωρήστε την καλωδίωση: Ελέγξτε τις συνδέσεις των ακροδεκτών για χαλάρωση και επιθεωρήστε τα καλώδια για τυχόν ζημιές ή σημάδια φθοράς.

- Εξετάστε το PLC: Ελέγξτε την κατάσταση του PLC (Programmable Logic Controller) για τυχόν κωδικούς σφάλματος ή ενδεικτικές λυχνίες. Η παρακολούθηση των σημάτων εισόδου/εξόδου μέσω του λογισμικού του PLC μπορεί να βοηθήσει στον γρήγορο εντοπισμό της πηγής του προβλήματος.

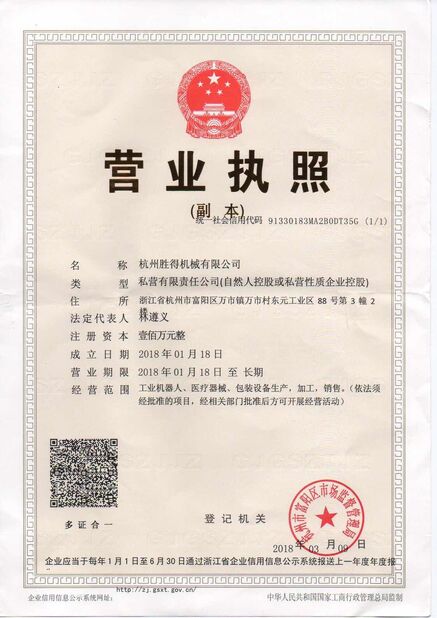

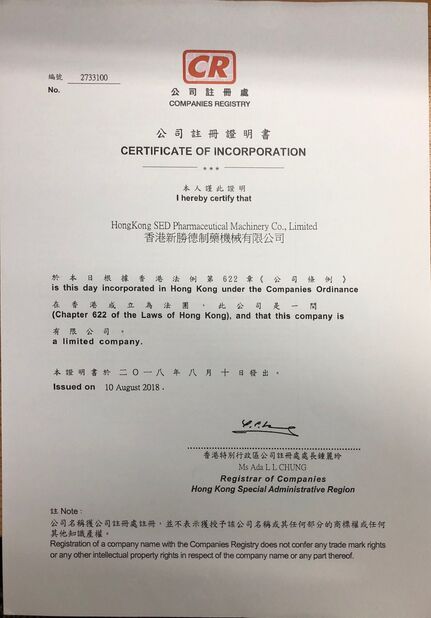

Για πολύπλοκα σφάλματα ή όταν πρέπει να αντικατασταθούν βασικά εξαρτήματα, συνιστάται να επικοινωνήσετε με τον κατασκευαστή του εξοπλισμού ή μια επαγγελματική ομάδα επισκευής. Κρατήστε τον σειριακό αριθμό του εξοπλισμού και τις πληροφορίες αγοράς, ώστε να μπορείτε να λάβετε γρήγορα γνήσια ανταλλακτικά και τεχνική υποστήριξη.

Σχέδιο προληπτικής συντήρησης

Για να διασφαλίσετε τη μακροχρόνια, σταθερή λειτουργία του εξοπλισμού σας, συνιστούμε την εφαρμογή του ακόλουθου χρονοδιαγράμματος συντήρησης.

| Συχνότητα |

Εργασία |

Λεπτομέρειες και πρότυπα |

| Καθημερινά |

1. Καθαρισμός μηχανής |

Καθαρίστε την επιφάνεια της μηχανής (ειδικά κεφαλές πωματισμού, ιμάντα μεταφοράς, ράγες) με πιστόλι αέρα και πανί για να αφαιρέσετε τη σκόνη, το λάδι και τα υπολείμματα προϊόντων μετά το κλείσιμο. |

| 2. Έλεγχος παροχής αέρα |

Ελέγξτε ότι η πίεση του αέρα είναι σταθερή εντός του απαιτούμενου εύρους (συνήθως 0,6~0,8 MPa). Αφαιρέστε το νερό από τον ρυθμιστή φίλτρου αέρα για να εξασφαλίσετε καθαρό, ξηρό αέρα. |

| 3. Βασική λίπανση |

Εφαρμόστε καθορισμένο ελαφρύ λιπαντικό λάδι σε μερικές βασικές εκτεθειμένες ράγες, ράβδους κυλίνδρων κ.λπ. Αποφύγετε τη μόλυνση φιαλών ή καπακιών. |

| 4. Οπτική και ακουστική επιθεώρηση |

Πραγματοποιήστε έναν βασικό έλεγχο για ασυνήθιστους θορύβους, χαλαρά μέρη ή άλλα εμφανή προβλήματα πριν από την εκκίνηση. |

| Εβδομαδιαία |

1. Έλεγχος συνδετήρων |

Ελέγξτε και σφίξτε όλες τις βίδες, τα μπουλόνια και τις συνδέσεις της πλάκας στερέωσης για να αποτρέψετε τη χαλάρωση λόγω δόνησης. |

| 2. Καθαρισμός αισθητήρων |

Απενεργοποίηση. Καθαρίστε απαλά τους φακούς/επιφάνειες ανίχνευσης όλων των φωτοηλεκτρικών αισθητήρων και των διακοπτών εγγύτητας με ένα μαντηλάκι αλκοόλης για να εξασφαλίσετε αξιόπιστη λειτουργία. |

| 3. Επιθεώρηση φθαρμένων εξαρτημάτων |

Ελέγξτε το επίπεδο φθοράς των αναλώσιμων όπως οι λαβές κεφαλής πωματισμού, οι δίσκοι τριβής, οι βεντούζες κενού, οι ιμάντες μεταφοράς και οι ράγες. Αξιολογήστε τη διάρκεια ζωής που απομένει. |

| 4. Δοκιμή λειτουργίας ασφαλείας |

Δοκιμάστε τη λειτουργικότητα των κουμπιών διακοπής έκτακτης ανάγκης και των προφυλακτήρων ασφαλείας. |

| Μηνιαία |

1. Ολοκληρωμένη λίπανση |

Λιπάνετε όλα τα καθορισμένα κινούμενα μέρη (ρουλεμάν, ράγες οδηγού, ρυθμιστικά, γρανάζια) με το κατάλληλο γράσο ή λάδι σύμφωνα με το εγχειρίδιο. |

| 2. Επιθεώρηση συστήματος κίνησης |

Ελέγξτε την τάση και τη φθορά των ιμάντων χρονισμού, των αλυσίδων. ρυθμίστε ή αντικαταστήστε εάν είναι απαραίτητο. Ελέγξτε τους κινητήρες για ομαλή και αθόρυβη λειτουργία. |

| 3. Βαθμονόμηση ροπής |

Χρησιμοποιήστε έναν πιστοποιημένο ελεγκτή ροπής για να πραγματοποιήσετε πολλαπλές μετρήσεις. Συγκρίνετε με την τιμή εμφάνισης της μηχανής και βαθμονομήστε στο απαιτούμενο εύρος διεργασίας. |

| 4. Έλεγχος πνευματικού συστήματος |

Επιθεωρήστε όλες τις συνδέσεις εύκαμπτων σωλήνων αέρα για διαρροές. Ελέγξτε τους κυλίνδρους για ομαλή και ισχυρή κίνηση. |

| Ετησίως |

1. Αντικατάσταση στεγανοποίησης |

Πραγματοποιήστε μια μεγάλη επισκευή. Αντικαταστήστε όλα τα κύρια εσωτερικά δακτυλίδια O, τις στεγανοποιήσεις και τις στεγανοποιήσεις πνευματικών βαλβίδων για να αποτρέψετε τη γήρανση και τις διαρροές. |

| 2. Επιθεώρηση κινητήρα και κίνησης |

Ελέγξτε τη λειτουργία και την ακρίβεια των σερβοκινητήρων, των κιβωτίων ταχυτήτων κ.λπ. Καθαρίστε τους ανεμιστήρες ψύξης του κινητήρα. Ελέγξτε τις ηλεκτρικές επαφές για σφίξιμο. |

| 3. Πλήρης επαναβαθμονόμηση μηχανής |

Πραγματοποιήστε μια ολοκληρωμένη βαθμονόμηση του επιπέδου της μηχανής, της συγκεντρικότητας κεφαλής πωματισμού-φιάλης, του ύψους ανύψωσης και άλλων μηχανικών παραμέτρων για την αποκατάσταση της ακρίβειας του εργοστασίου. |

| 4. Έλεγχος συστήματος ελέγχου |

Καθαρίστε τη σκόνη μέσα στο ηλεκτρικό ντουλάπι. Ελέγξτε τις επαφές των διακοπτών, των επαφέων, των ρελέ. Δημιουργήστε αντίγραφα ασφαλείας του προγράμματος PLC. |

Συμπέρασμα

Η αυτόματη μηχανή πωματισμού είναι ζωτικής σημασίας για την επίτευξη σταθερής ποιότητας και αποτελεσματικής λειτουργίας σε μια γραμμή φαρμακευτικής συσκευασίας.

Με την κατανόηση των κοινών βλαβών, την εφαρμογή μεθόδων γρήγορης αντιμετώπισης προβλημάτων και την τήρηση ενός σχεδίου προληπτικής συντήρησης, οι εταιρείες μπορούν να βελτιστοποιήσουν την παραγωγή, να διασφαλίσουν τη συμμόρφωση και να διατηρήσουν ένα ανταγωνιστικό πλεονέκτημα στην αγορά.

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!  Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες!

Το μήνυμά σας πρέπει να αποτελείται από 20-3.000 χαρακτήρες! Παρακαλούμε ελέγξτε το email σας!

Παρακαλούμε ελέγξτε το email σας!